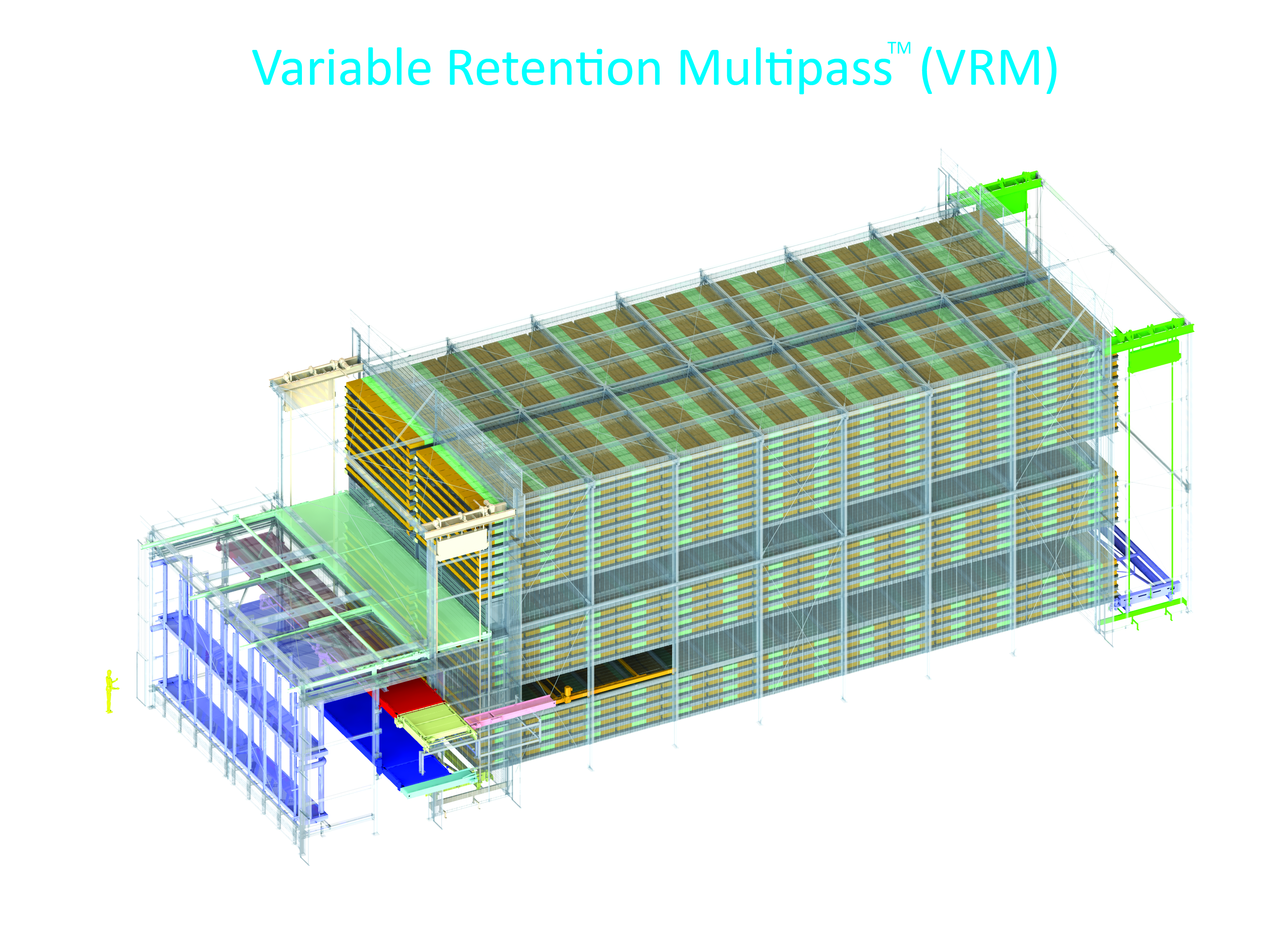

Variable Retention Multipass (VRM)

The FSL Variable Retention Multipass System

Background

Large Capacity Carton Freezers: Up to around 20,000 holding capacity at any one time.

The variable retention time concept was first introduced to the market in 1980 by the founder of Freezing Solutions Limited. Over the years several mechanical improvements evolved however the air distribution remained unaltered as a single pass counter air to product flow. With the rapid increase in freezer sizes (capacity) between 2000 to 2010 it was observed that freezing consistency was becoming a concern as was the energy usage when compared with small to medium sized freezers.

Extensive research into these two major issues led to the development of the Patented Multipass System which has been incorporated into the variable retention time freezers now referred to as VRM (Multiple Retention Multipass).

Click on the link below to view diagrams:

Variable_Retention_Multipass_Drawing.pdf

The FSL Advantage:

Our solutions are based on combining proven modules that have worked successfully around the world in many applications. Our team’s combined 150+ years international experience in packaged product freezing, from 30kg meat cartons to the small “ready meal” market, provides FSL with the experience to confidently offer an individual solution to exactly match each client’s requirements.

The refrigeration airflow employed in our freezer designs is of a true counter flow nature, providing the coldest air to the coldest product and improving final product temperature. This feature reduces enclosure size, refrigeration charge and offers substantial savings in relation to energy costs and impact on the carbon footprint.

Mechanical design is of an exceptionally high standard with an emphasis on reliability. From the previous systems that have successfully handled a variety of products, there are a multitude of criteria that, together with a commitment to continual improvement, ensures progressive enhancements are included in each new solution we offer.

The philosophy of Total Productive Maintenance (TPM) is a guiding principal in the execution of each machine.

Counter-flow, Multi-pass Airflow:

The refrigeration system as a whole is often the least understood aspect of freezer design, both by customers and practitioners alike, however it is in this area that the most effective cost reductions can be achieved.

While there are several ways to reduce freezer operating costs, the most dramatic energy savings are derived from reduced fan power into the system – the most practical time to take advantage of this significant benefit is during the selection of a new freezing system.

Specifying FSL’s patented Multi-pass Airflow at the initial design phase ensures sufficient space is allowed for the deeper evaporator that is used in this application.

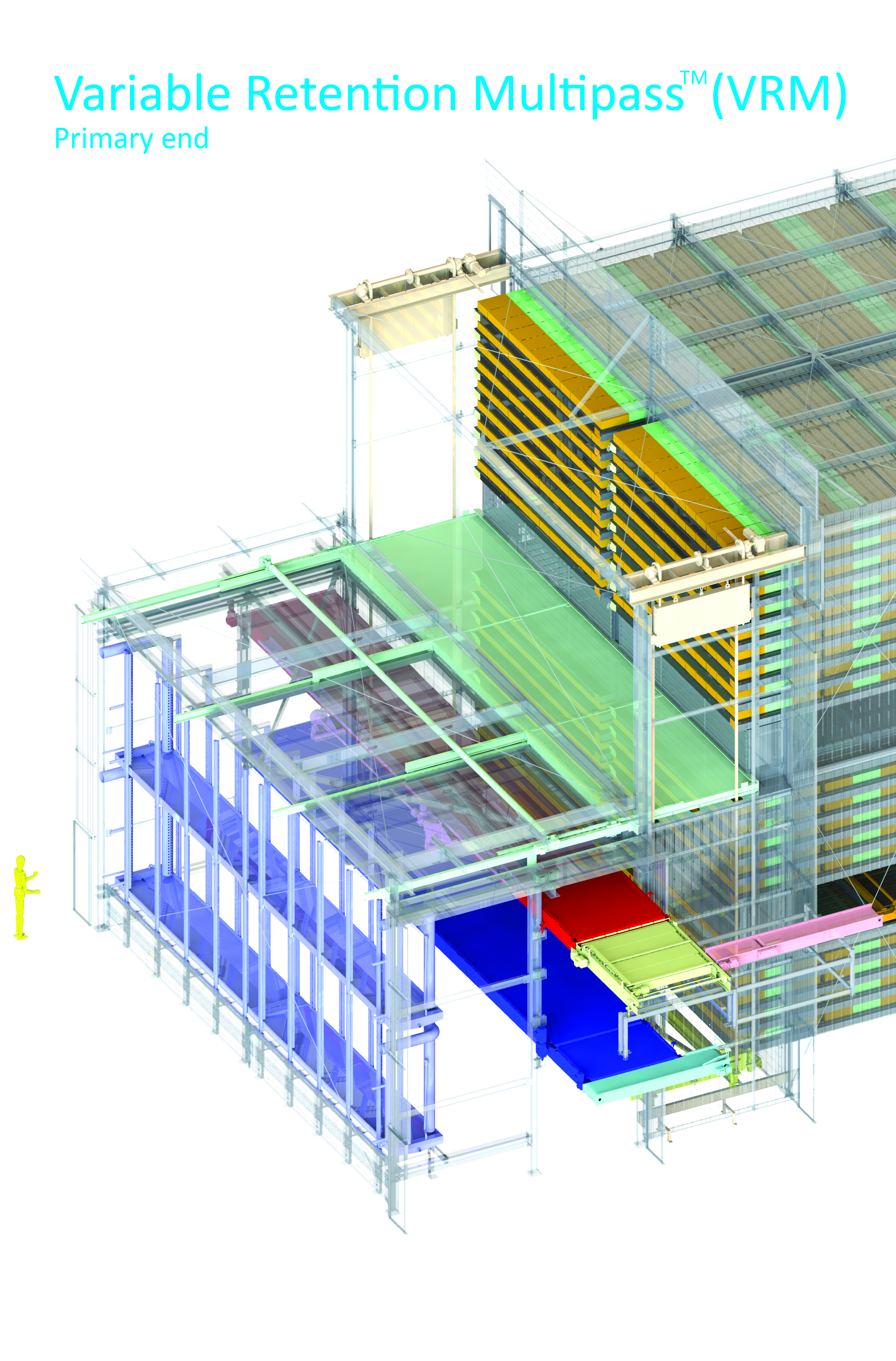

The Multipass Transition Gate:

Located at the Primary Elevator is the Multipass Transition Gate ( shown on the VRM elevation drawing) that retracts to allow the Loader to pass through. When the Loader is not travelling between the upper and lower magazines of the VRM, the gate remains closed to maintain airflow separation.

Fan power and energy savings:

Fan power requirement is determined by the volume of air to be circulated within the freezer and the corresponding system pressure drop. Having the air in contact with the product over multiple passes (normally two) then the volume of air is significantly reduced (normally halved).

The combination of these features contributes to significant energy savings. In real terms this amounts to savings of millions of dollars over the life of the freezer.

Product temperature consistency:

The Multipass design in addition to being more economical in terms of the items listed above ensures offers a proven superior air distribution circulation over all the products no matter where the product is located in the system.

Freezing Solutions Ltd work in collaboration with Food Processing Solutions Corporation (FPS)

Click on the link to view their details www.fpscorp.ca